You Are Here:Home > News Center

> Company Dynamics

News navigation

Recommended news

What are the application industries of PCR regenerated materials

source:lastz.cn | Release time:2024-11-12

The application industry of PCR regenerated materials is wide, as follows:

1. Automotive industry:

Interior components: can be used to manufacture interior parts of automobiles, such as instrument panels, door panels, seat materials, interior decorative strips, etc. Compared to native plastics, PCR recycled materials not only meet the performance requirements of interior parts, but also reduce costs and carbon emissions, meeting the automotive industry's demand for environmentally friendly materials.

Non structural components: Some non structural components on automobiles, such as bumpers, fenders, radiator grilles, etc., can also use PCR recycled materials. These components have certain requirements for the strength and toughness of the materials. The processed PCR regenerated materials can meet the corresponding performance standards, and the use of regenerated materials helps automobile manufacturers meet environmental regulations and sustainable development requirements.

2. Electronic and electrical industry:

Shell and components: PCR regenerated materials can be used to produce shells for electronic and electrical products, such as TV cases, computer cases, printer cases, etc. It has good insulation and mechanical properties, which can meet the requirements of electronic and electrical products for shell materials. Meanwhile, for some internal components such as the base and bracket of electrical appliances, PCR recycled materials can also be used for manufacturing to reduce costs and improve resource utilization.

Wire and cable: PCR regenerated materials also have certain applications in the insulation and sheath layers of wire and cable. Recycled materials that have undergone special treatment and processing can have good insulation and wear resistance properties, ensuring the safe use of wires and cables.

3. Packaging industry:

Food packaging: PCR regenerated materials can be used to manufacture food packaging containers, such as beverage bottles, food packaging bags, food turnover boxes, etc. But strict food hygiene and safety standards need to be met to ensure that recycled materials do not contain harmful substances and will not contaminate food.

Packaging for daily chemical products: PCR recycled materials can also be used for packaging bottles, boxes, etc. for shampoo, shower gel, cosmetics, and other daily chemical products. These packaging materials have certain requirements for appearance and physical properties. After modification and processing, PCR recycled materials can meet the packaging needs of daily chemical products and have environmentally friendly and sustainable characteristics.

Logistics packaging: In logistics transportation, PCR regenerated materials can be used to manufacture logistics packaging materials such as pallets, packaging boxes, and wrapping films. These materials need to have a certain strength and durability to ensure the safe transportation of goods, and PCR regenerated materials can improve their performance by adding enhancers and other methods.

4. Construction industry:

Construction pipes: PCR regenerated materials can be used to produce pipes for water supply, drainage, threading, and other construction purposes. These pipes need to have good corrosion resistance, pressure resistance, and sealing properties. After appropriate processing and treatment, PCR recycled materials can meet the requirements of building pipes, reduce construction costs, and minimize environmental impact.

Building panels: Panels used in the construction industry, such as decorative panels, soundproofing panels, insulation panels, etc., can also be manufactured using PCR recycled materials. PCR recycled material board has certain strength and thermal insulation performance, which can meet the demand of the construction industry for board and reduce the generation of construction waste.

5. Household goods industry:

Furniture: Some furniture components, such as the frames of tables and chairs, side panels of drawers, etc., can be manufactured using PCR recycled materials. Through appropriate design and processing, PCR recycled furniture can have good appearance and performance, while also complying with environmental protection concepts, and is receiving increasing attention from consumers.

Home decorations: Home decorations such as photo frames, vases, and ornaments can also use PCR recycled materials. These decorations have certain requirements for the color, shape, and texture of the materials. PCR recycled materials can meet these requirements through dyeing, injection molding, and other processes, and can create unique decorative effects.

6. Toy industry: PCR recycled materials can be used to manufacture toys such as plastic building blocks, puzzles, dolls, etc. The toy industry has high requirements for material safety, and PCR recycled materials need to undergo strict testing and certification to ensure that they do not contain harmful substances and meet the safety standards of toys. Using PCR regenerated materials to manufacture toys not only reduces costs but also minimizes environmental impact, in line with the sustainable development trend of the toy industry.

7. Agricultural industry:

Agricultural film: PCR regenerated materials can be used to produce agricultural films, such as plastic films, greenhouse films, etc. These films need to have good transparency, insulation, and weather resistance. After modification and processing, PCR regenerated materials can meet the requirements of agricultural films and reduce soil pollution.

Irrigation pipes: In agricultural irrigation systems, PCR regenerated materials can be used to manufacture irrigation pipes and fittings. These pipes need to have good corrosion resistance and pressure resistance to ensure the normal operation of irrigation systems. PCR regenerated materials can meet these requirements and reduce agricultural production costs.

1. Automotive industry:

Interior components: can be used to manufacture interior parts of automobiles, such as instrument panels, door panels, seat materials, interior decorative strips, etc. Compared to native plastics, PCR recycled materials not only meet the performance requirements of interior parts, but also reduce costs and carbon emissions, meeting the automotive industry's demand for environmentally friendly materials.

Non structural components: Some non structural components on automobiles, such as bumpers, fenders, radiator grilles, etc., can also use PCR recycled materials. These components have certain requirements for the strength and toughness of the materials. The processed PCR regenerated materials can meet the corresponding performance standards, and the use of regenerated materials helps automobile manufacturers meet environmental regulations and sustainable development requirements.

2. Electronic and electrical industry:

Shell and components: PCR regenerated materials can be used to produce shells for electronic and electrical products, such as TV cases, computer cases, printer cases, etc. It has good insulation and mechanical properties, which can meet the requirements of electronic and electrical products for shell materials. Meanwhile, for some internal components such as the base and bracket of electrical appliances, PCR recycled materials can also be used for manufacturing to reduce costs and improve resource utilization.

Wire and cable: PCR regenerated materials also have certain applications in the insulation and sheath layers of wire and cable. Recycled materials that have undergone special treatment and processing can have good insulation and wear resistance properties, ensuring the safe use of wires and cables.

3. Packaging industry:

Food packaging: PCR regenerated materials can be used to manufacture food packaging containers, such as beverage bottles, food packaging bags, food turnover boxes, etc. But strict food hygiene and safety standards need to be met to ensure that recycled materials do not contain harmful substances and will not contaminate food.

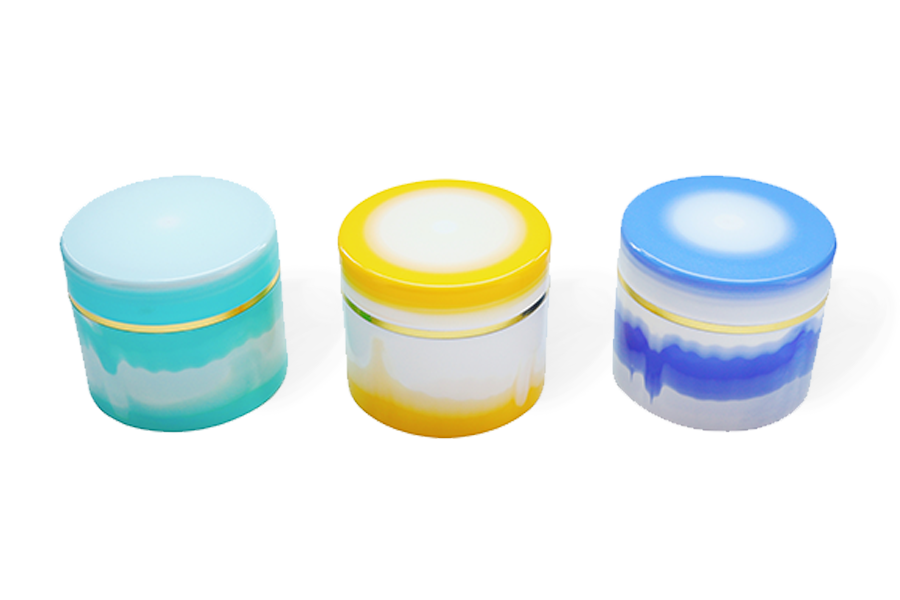

Packaging for daily chemical products: PCR recycled materials can also be used for packaging bottles, boxes, etc. for shampoo, shower gel, cosmetics, and other daily chemical products. These packaging materials have certain requirements for appearance and physical properties. After modification and processing, PCR recycled materials can meet the packaging needs of daily chemical products and have environmentally friendly and sustainable characteristics.

Logistics packaging: In logistics transportation, PCR regenerated materials can be used to manufacture logistics packaging materials such as pallets, packaging boxes, and wrapping films. These materials need to have a certain strength and durability to ensure the safe transportation of goods, and PCR regenerated materials can improve their performance by adding enhancers and other methods.

4. Construction industry:

Construction pipes: PCR regenerated materials can be used to produce pipes for water supply, drainage, threading, and other construction purposes. These pipes need to have good corrosion resistance, pressure resistance, and sealing properties. After appropriate processing and treatment, PCR recycled materials can meet the requirements of building pipes, reduce construction costs, and minimize environmental impact.

Building panels: Panels used in the construction industry, such as decorative panels, soundproofing panels, insulation panels, etc., can also be manufactured using PCR recycled materials. PCR recycled material board has certain strength and thermal insulation performance, which can meet the demand of the construction industry for board and reduce the generation of construction waste.

5. Household goods industry:

Furniture: Some furniture components, such as the frames of tables and chairs, side panels of drawers, etc., can be manufactured using PCR recycled materials. Through appropriate design and processing, PCR recycled furniture can have good appearance and performance, while also complying with environmental protection concepts, and is receiving increasing attention from consumers.

Home decorations: Home decorations such as photo frames, vases, and ornaments can also use PCR recycled materials. These decorations have certain requirements for the color, shape, and texture of the materials. PCR recycled materials can meet these requirements through dyeing, injection molding, and other processes, and can create unique decorative effects.

6. Toy industry: PCR recycled materials can be used to manufacture toys such as plastic building blocks, puzzles, dolls, etc. The toy industry has high requirements for material safety, and PCR recycled materials need to undergo strict testing and certification to ensure that they do not contain harmful substances and meet the safety standards of toys. Using PCR regenerated materials to manufacture toys not only reduces costs but also minimizes environmental impact, in line with the sustainable development trend of the toy industry.

7. Agricultural industry:

Agricultural film: PCR regenerated materials can be used to produce agricultural films, such as plastic films, greenhouse films, etc. These films need to have good transparency, insulation, and weather resistance. After modification and processing, PCR regenerated materials can meet the requirements of agricultural films and reduce soil pollution.

Irrigation pipes: In agricultural irrigation systems, PCR regenerated materials can be used to manufacture irrigation pipes and fittings. These pipes need to have good corrosion resistance and pressure resistance to ensure the normal operation of irrigation systems. PCR regenerated materials can meet these requirements and reduce agricultural production costs.

Previous:

period

Next:

What are the advantages of PP Cream Tank Series

【Related Products】

- CHANGSHU SHINE PLASTIC INDUSTRY CO.,LTD Phone:0512-52557888 Mailbox:shenshisuye@163.com Company address:No. 20 Guangyuan Road, South Development Zone, Zhitang Town, Changshu City, Jiangsu Province

-

Scan your phone

Scan your phone

wechat number:

wechat number:

home

home

WeChat

WeChat

telephone

telephone